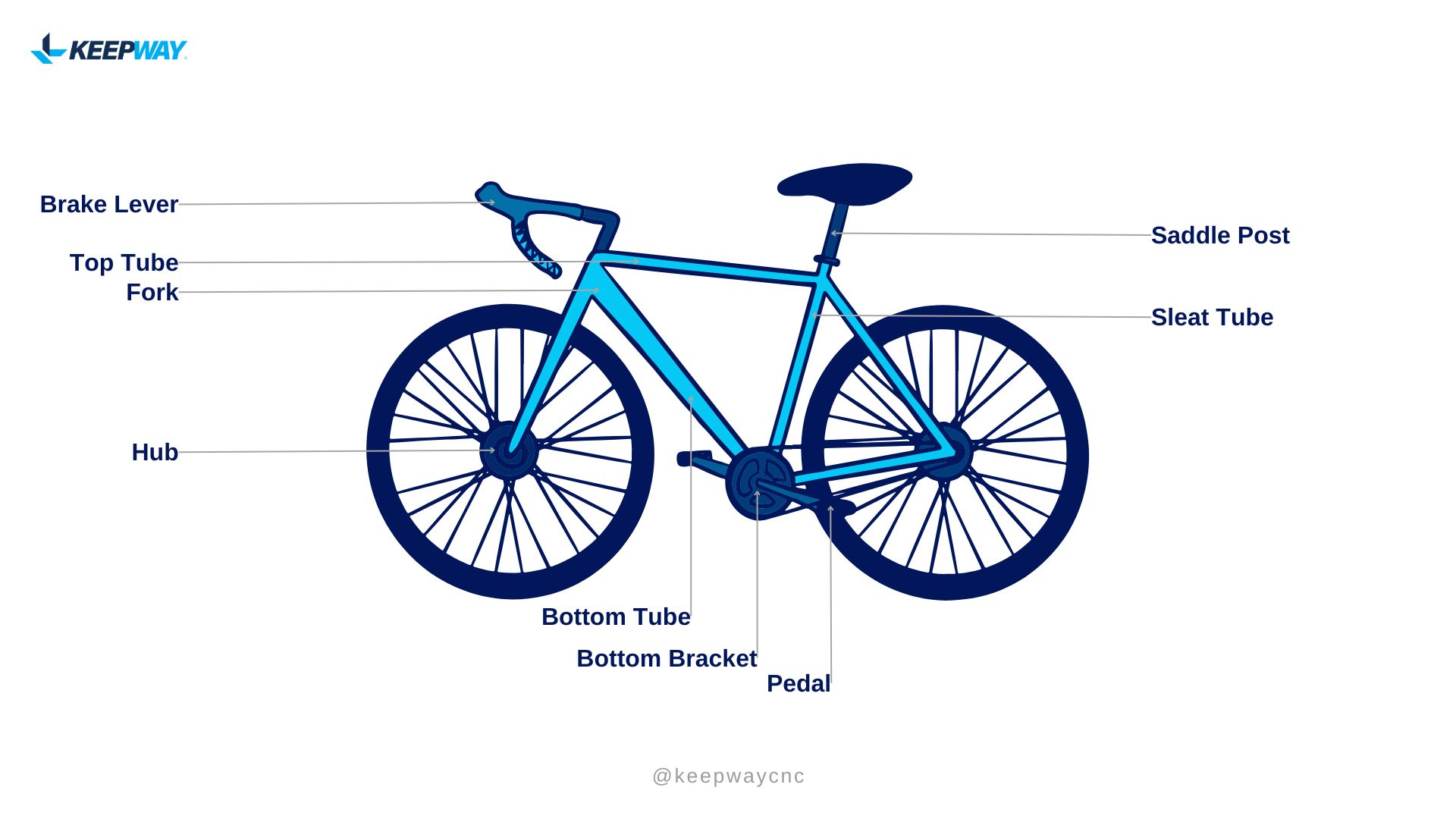

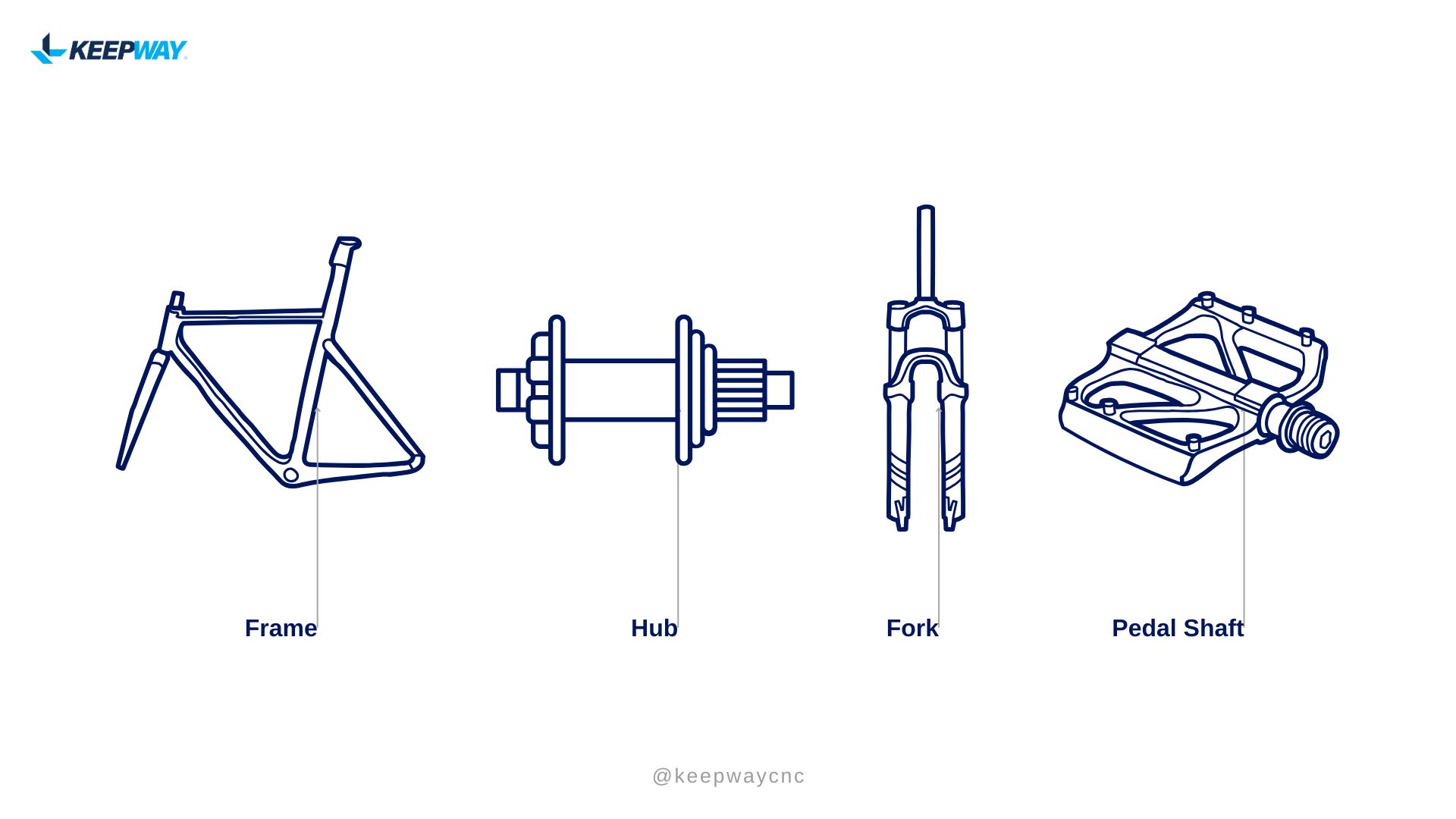

The Cycling Industry

Turning Center (CNC Lathe)

Machining Center

Turning Center

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 500mm

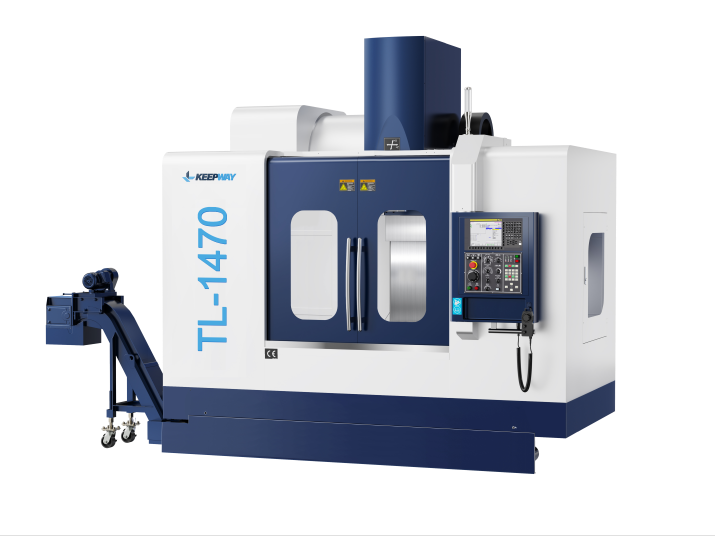

Machining Center

X-axis Travel: 1000mm

Y-axis Travel: 600mm

Z-axis Travel: 600mm

Turning Center

Chuck size: 6"

Max turning diameter: 180mm

Max turning length: 300mm

Turning Center

Chuck size: 8"

Max turning diameter: 260mm

Max turning length: 300mm

Automation Solution

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 500mm

Turning Center

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 750mm

Machining Center

X-axis Travel: 1600mm

Y-axis Travel: 800mm

Z-axis Travel: 700mm

Turning Center

Chuck size: 10"

Max turning diameter: 360mm

Max turning length: 750mm

Machining Center

X-axis Travel: 750mm

Y-axis Travel: 500mm

Z-axis Travel: 500mm

Machining Center

X-axis Travel: 1400mm

Y-axis Travel: 700mm

Z-axis Travel: 600mm

Machining Center

X-axis Travel: 1200mm

Y-axis Travel: 600mm

Z-axis Travel: 600mm

Turning Center

Chuck size: 10"

Max turning diameter: 360mm

Max turning length: 500mm

Automation Solution

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 500mm