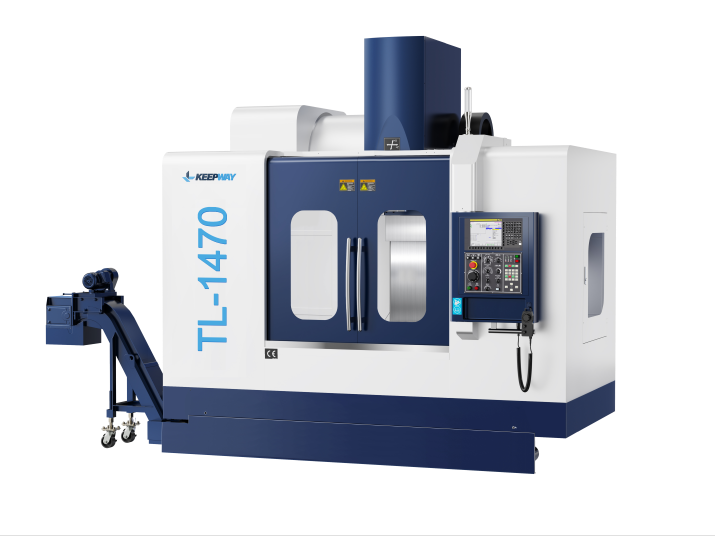

Machining Center

TL-1470

TL Series [Linear]

Introducing our machining center series with linear guideways, designed for high-efficiency precision machining.

We are committed to traditional production methods. Our careful material selection sets the industry standard for quality.

This machining center is customized to meet your specific needs, ensuring maximum efficiency.

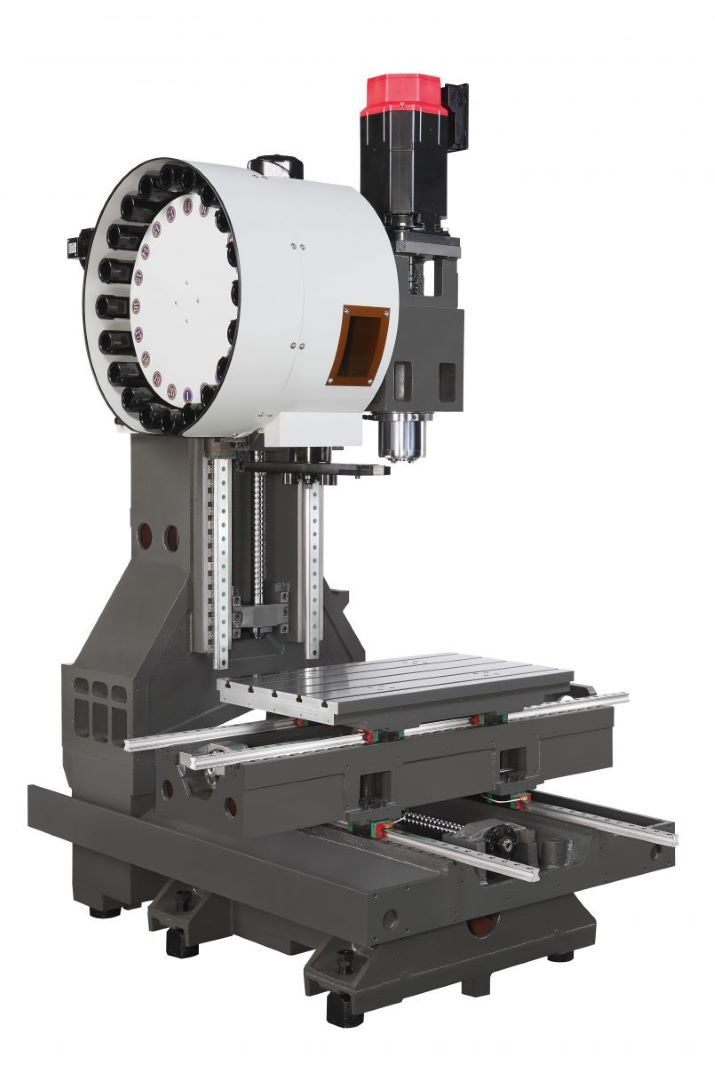

Stucture Design

- We use MIT castings for our machining center's body structure, ensuring top quality for our users. This choice maintains precise accuracy during metal cutting and extends the lifespan of cutting tools. The Y-shaped interior design provides strong support, enhancing overall precision and performance.

Spindle

- High Speeds: Direct-driven spindles can achieve very high rotational speeds, allowing for faster cutting and machining operations. This is particularly advantageous when precision and speed are critical.

- Improved Accuracy: Direct-driven spindles typically have better speed control and accuracy compared to belt-driven or gear-driven spindles. This precision is essential for achieving tight tolerances and high-quality surface finishes.

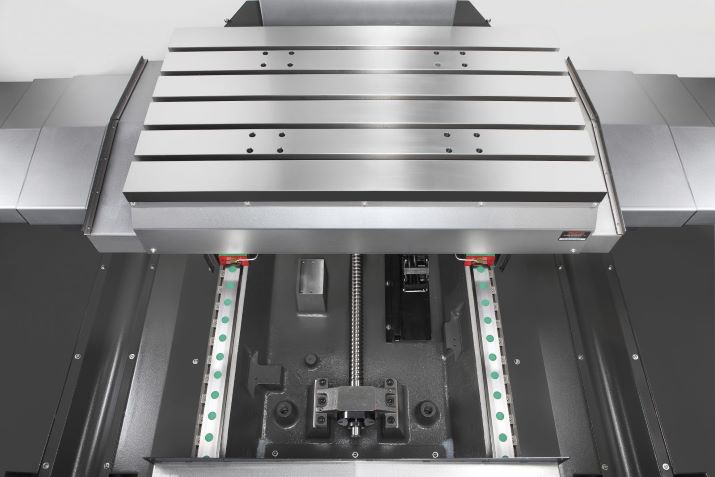

Ball Screw

- The implementation of ball screw pretension design across all axes effectively reduces the necessity for machine body backlash compensation. The repeatability and positioning accuracy are meticulously preserved and upheld to the highest standards.

Guideway

- Roller-type linear guideways have been implemented across the TL series products. The incorporation of these rolling guideways not only ensures fast operational speeds but also guarantees the capability to maintain stringent tolerance levels.

- Roller-type guideways exhibit superior resistance to vibration damping, deflecting significantly less under the impact of repetitive loads. This substantial reduction in vibration levels enhances cutting capacity, refines part surface finishes, and significantly prolongs tool lifespan.

- The implementation of ball screw pretension design across all axes effectively reduces the necessity for machine body backlash compensation. The repeatability and positioning accuracy are meticulously preserved and upheld to the highest standards.

| Item | TL-1470 |

|---|---|

| Controller | Fanuc 0i-MF Plus |

| Spindle motor | 15/18.5 kw |

| X/Y/Z axis motor | 4.0/4.0/4.0 kw |

| Coolant pump motor | 600 w |

| Magazine motor | 400 w |

| Chip conveyor motor | 1000 w |

| Spindle driven type | Direct |

| Spindle Speed | 10000 rpm |

| Spindle taper | BT-40 |

| Spindle diameter | Φ150 mm |

| Spindle bearing grade | P4 |

| X-axis travel | 1400 mm |

| Y-axis travel | 700 mm |

| Z-axis travel | 600 mm |

| Spindle nose to table | 150-750 mm |

| Spindle center to z-rail | 740 mm |

| Ballscrew grade | C3 |

| X/Y/Z ballscrew | X/Y:Φ50xP10, Z:Φ40xP10 |

| X/Y/Z linear guideway | 45x2/45x4/45x2 |

| X/Y/Z cutting feed rate | 10/10/10 m/min |

| X/Y/Z rapid feed rate | 30/30/24 m/min |

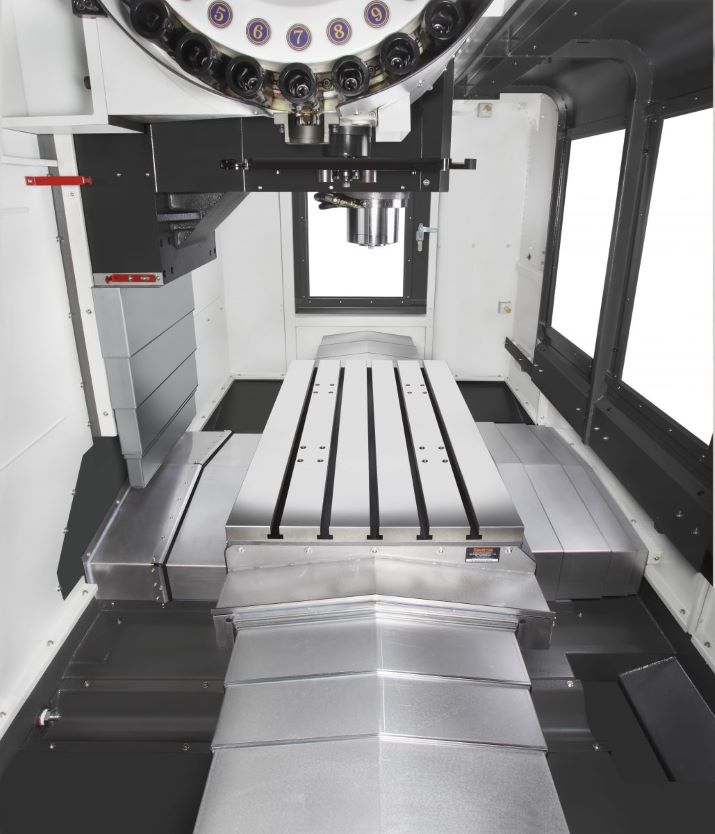

| Table size | 1450x700 mm |

| T-slot (number x width x pitch) | 5x18x130 mm |

| Maximum table load | 1200 kg |

| Magazine type | Arm |

| Tool capacity | 24 |

| Tool selection | Two-way Selection |

| Maximum tool length / diameter | 300xΦ80 mm |

| Maximum tool weight | 7 kg |

| Tool shank | 45° |

| Chip conveyor | Dual-screw |

| Air pressure | ≧6.5 |

| Power voltage | 220/380 v |

| Power capacity | 30 kva |

| Floor space (LxWxH) | 4250x3610x3150 mm |

| Machine Weight | 9700 kg |

DISCLAIMER : KAIFENG MACHINERY CO., LTD. RESERVES THE RIGHT TO AMEND ANY SPECIFICATIONS WITHOUT PRIOR NOTICE.

| Item | TL-1470 |

|---|---|

| Controller | Fanuc 0i-MF Plus |

| Spindle motor | 15/18.5 kw |

| X/Y/Z axis motor | 4.0/4.0/4.0 kw |

| Coolant pump motor | 600 w |

| Magazine motor | 400 w |

| Chip conveyor motor | 1000 w |

| Spindle driven type | Direct |

| Spindle Speed | 10000 rpm |

| Spindle taper | BT-40 |

| Spindle diameter | Φ150 mm |

| Spindle bearing grade | P4 |

| X-axis travel | 55.1” |

| Y-axis travel | 27.6” |

| Z-axis travel | 23.6” |

| Spindle nose to table | 5.9”-29.5” |

| Spindle center to z-rail | 29.1” |

| Ballscrew grade | C3 |

| X/Y/Z ballscrew | X/Y:Φ50xP10, Z:Φ40xP10 |

| X/Y/Z linear guideway | 6/8/6 |

| X/Y/Z cutting feed rate | 10/10/10 m/min |

| X/Y/Z rapid feed rate | 30/30/24 m/min |

| Table size | 57.1”x27.6” |

| T-slot (number x width x pitch) | 5x0.7”x5.1” |

| Maximum table load | 1200 kg |

| Magazine type | Arm |

| Tool capacity | 24 |

| Tool selection | Two-way Selection |

| Maximum tool length / diameter | 300xΦ80 |

| Maximum tool weight | 7 kg |

| Tool shank | 90° |

| Chip conveyor | Dual-screw |

| Air pressure | ≧6.5 |

| Power voltage | 220/380 v |

| Power capacity | 30 kva |

| Floor space (LxWxH) | 4250x3610x3150 mm |

| Machine Weight | 9700 kg |

DISCLAIMER : KAIFENG MACHINERY CO., LTD. RESERVES THE RIGHT TO AMEND ANY SPECIFICATIONS WITHOUT PRIOR NOTICE.

Indexing Rotary Table

- A combination of high precision bronze / nickel worm wheel and case hardened steel worm screw ensures long term indexing accuracy. The table diameter ranges from Ø170-Ø320mm (Including Ø170, Ø200, Ø250 and Ø320).

Indexing Rotary Table

- A combination of high precision bronze / nickel worm wheel and case hardened steel worm screw ensures long term indexing accuracy.

- The dividing plate is configured with a bridge-style spacer assembly (including the spacer, large base plate, disc-type tailstock, L-shaped support block, and flange plate).

- The dividing plate is widely used for sizes ranging from Ø170 to Ø320mm.

Tilting Rotary Table

- Easy installation and operation. The left tilt, right tilt, and the rotary axis all use the mechanism of full circumference hydraulic bake. Matching 5 axes M/C for continuing machining, it could provide bigger tilting angle: -110°~+110°.

- Large-through-hole diameter provides bigger space for work piece setup with fixtures. The table diameter ranges from Ø200-Ø320mm.

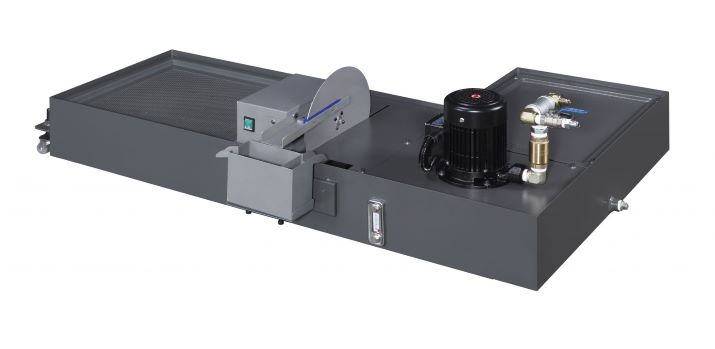

Oil Skimmer

- Recycling opportunities: to re-use the skimmed oil elsewhere or sell it for recycling.

- Extend coolant life: to have oil free coolant can also extend its usefulness and effectiveness, reducing the expense on maintenance and coolant replacement.

- Esthetic benefits: to cut down on the amount of smoke generated from the cutting tool coming into contact with coolant thereby creating a cleaner workplace.

Oil Mist Collector

- Environmental Protection: Effectively collects and recycles oil mist, reducing air pollution and protecting the work environment.

- Cost Reduction: Recovered oil mist can be reused, lowering the consumption costs of lubricating oil.

- Enhanced Safety: Reduces the accumulation of oil mist in the workplace, decreasing the risk of fire and slips.

- Improved Working Conditions: Lowers oil mist concentration, enhancing worker health and comfort.

- Extended Equipment Life: Keeps machine parts clean, reducing corrosion and wear from oil mist.