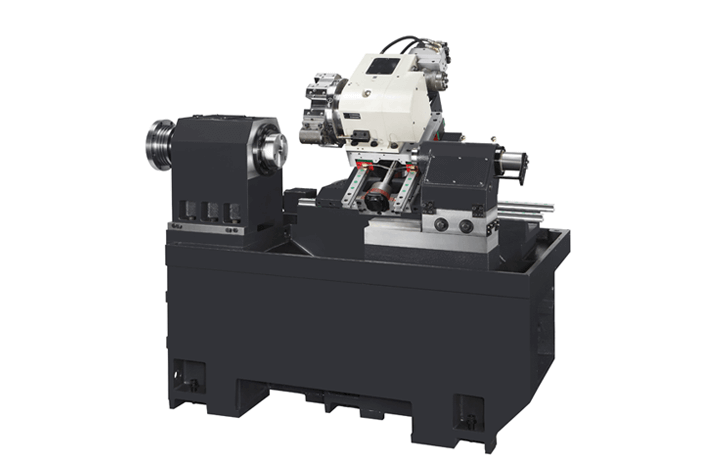

Turning Center

KT-18

KT Series [Linear]

Incorporating a 30˚ slant wedge saddle design and heavy-duty structure foundation, an optimization of the rigidity of the overall machine structure is applied to the headstock, turret, and tailstock.

Structure Design

- Incorporating a 30° slant wedge saddle design and a robust heavy-duty foundation, we have strategically optimized the overall machine structure's rigidity, specifically focusing on enhancing the stability of the headstock, turret, and tailstock components.

- Our unwavering commitment to quality is exemplified by our use of MIT castings, ensuring the highest standards of quality assurance for our users. We place a strong emphasis on delivering enduring precision in metal cutting and extending the lifespan of cutting tools.

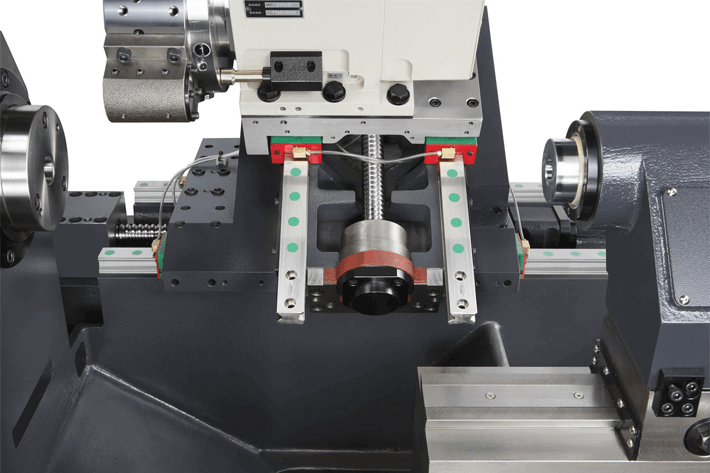

Linear Guideway

- The implementation of linear guideways effectively reduces friction while simultaneously offering exceptional positioning accuracy. From an after-sales maintenance perspective, the linear guideway is relatively user-friendly, allowing for straightforward maintenance by simply replacing the sliding blocks and guideway components to restore optimal performance.

Ball Screw

- All our products are equipped with C3 class ball screws, ensuring high positioning accuracy. We employ a ball screw pretension design across all axes to effectively minimize the need for backlash compensation in the machine body. This results in exceptional repeatability and positioning accuracy.

| Item | KT-18 |

|---|---|

| Controller | Fanuc 0i-TF Plus |

| Bed swing diameter | 450 mm |

| Saddle swing diameter | 280 mm |

| Maximum turning diameter | 260 mm |

| Maximum turning length | 300 mm |

| Bar capacity | 52 mm |

| Power chuck diameter | 8” |

| Spindle motor power | 7.5/11 kw |

| Spindle speed | 5000 rpm |

| Spindle nose taper | A2-6 |

| Spindle bearing diameter | 100 mm |

| Spindle taper | 1/20 |

| X-axis travel | 125+20 mm |

| Z-axis travel | 300 mm |

| X-axis rapid feed rate | 24 m/min |

| Z-axis rapid feed rate | 30 m/min |

| Guide way type | Linear |

| Turret driven type | Servo |

| Tool capacity | 8T |

| OD tool shank size | 25 mm |

| ID tool shank size | 32 mm |

| Tailstock travel positioning | Hydraulic |

| Tailstock quill travel | 80 mm |

| Tailstock base travel | 200 mm |

| Quill taper size | MT#4 |

| Quill taper diameter | 70 mm |

| Floor space (LxWxH) | 2790x1542x1713 mm |

| Machine weight | 3300 kg |

DISCLAIMER : KAIFENG MACHINERY CO., LTD. RESERVES THE RIGHT TO AMEND ANY SPECIFICATIONS WITHOUT PRIOR NOTICE.

| Item | KT-18 |

|---|---|

| Controller | Fanuc 0i-TF Plus |

| Bed swing diameter | 17.7” |

| Saddle swing diameter | 11.0” |

| Maximum turning diameter | 10.2” |

| Maximum turning length | 11.8” |

| Bar capacity | 2.0” |

| Power chuck diameter | 8” |

| Spindle motor power | 7.5/11 kw |

| Spindle speed | 5000 rpm |

| Spindle nose taper | A2-6 |

| Spindle bearing diameter | 3.9” |

| Spindle taper | 1/20 |

| X-axis travel | 4.9+0.8” |

| Z-axis travel | 11.81” |

| X-axis rapid feed rate | 24 m/min |

| Z-axis rapid feed rate | 30 m/min |

| Guide way type | Linear |

| Turret driven type | Servo |

| Tool capacity | 8T |

| OD tool shank size | 1.0” |

| ID tool shank size | 1.3” |

| Tailstock travel positioning | Hydraulic |

| Tailstock quill travel | 3.1” |

| Tailstock base travel | 7.9” |

| Quill taper size | MT#4 |

| Quill taper diameter | 2.8” |

| Floor space (LxWxH) | 2790x1542x1713 mm |

| Machine weight | 3300 kg |

DISCLAIMER : KAIFENG MACHINERY CO., LTD. RESERVES THE RIGHT TO AMEND ANY SPECIFICATIONS WITHOUT PRIOR NOTICE.

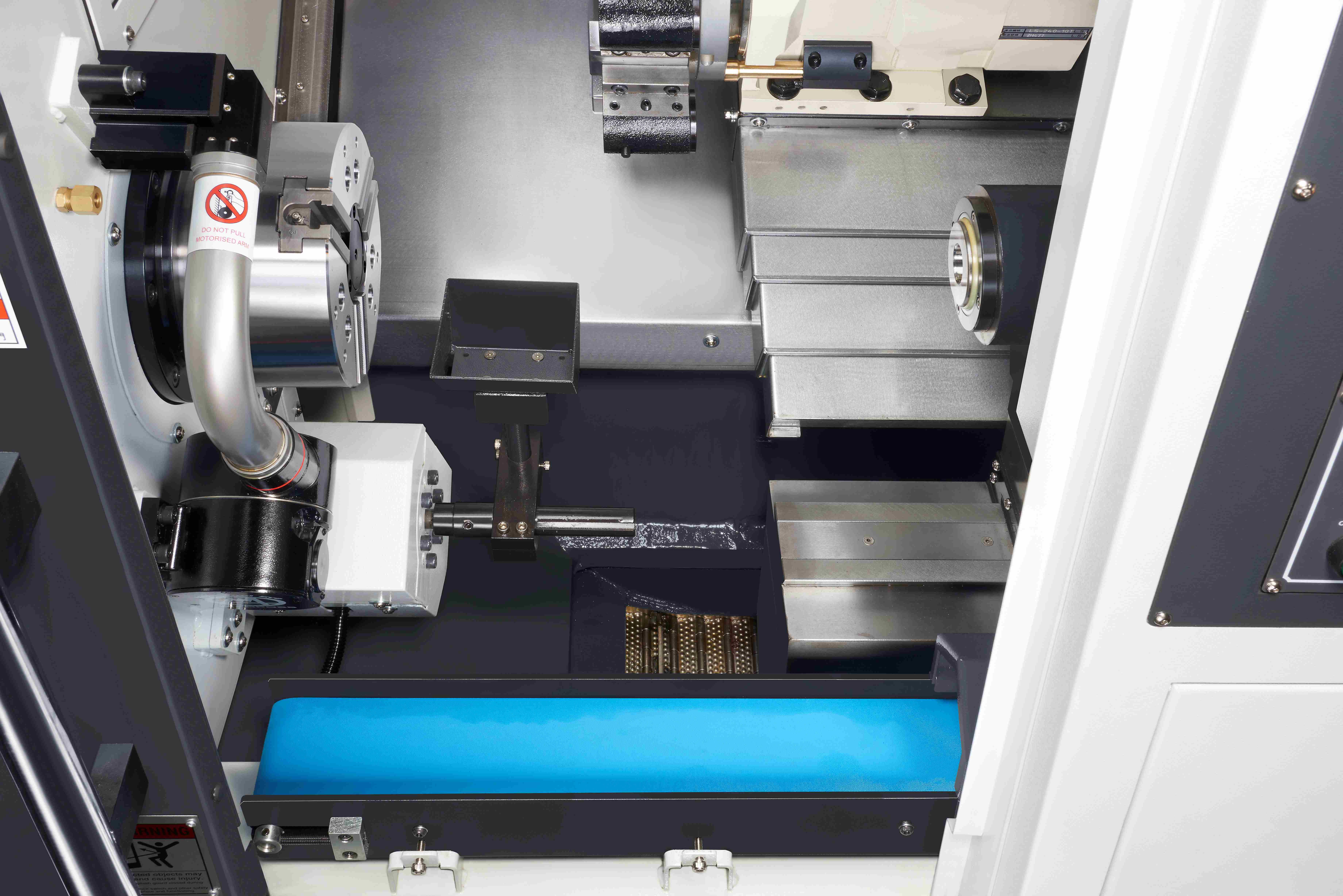

Gantry Loading and Unloading System

- A Gantry Loading/Unloading System, when used with a CNC machine, is an automated material handling system designed to load and unload workpieces into and out of the lathe's work area.

- Increased Productivity: Automation reduces downtime between machining operations, leading to higher throughput and productivity.

- Reduced Labor Costs: Operators are freed up to perform more skilled tasks or oversee multiple machines, reducing the need for dedicated machine tenders.

- 24/7 Operation: Automated systems can run continuously, allowing for unmanned machining during nights or weekends.

Bar Feeder

- The optional automatic bar feeder enhances productivity by reducing material feeding time. It imposes no limitations on spindle speed or material shape.

- Various feeding torques can be applied to accommodate different material diameters, weights, and lengths, preventing material deformation.

Parts Catcher

- The parts catcher automatically receives finished parts, offering convenient access without the need to open the machine door.

- This highly efficient system is operator friendly.

Tool Presetter

- The optional Renishaw or Marposs tool probe accessory significantly boosts production output and minimizes machine idle time. It precisely measures cutting tool length and diameter, providing solutions for tool setting, broken tool detection, component setup, in-cycle gauging, and initial component inspection, with automatic offset updates.

Oil Mist Collector

- Environmental Protection: Effectively collects and recycles oil mist, reducing air pollution and protecting the work environment.

- Cost Reduction: Recovered oil mist can be reused, lowering the consumption costs of lubricating oil.

- Enhanced Safety: Reduces the accumulation of oil mist in the workplace, decreasing the risk of fire and slips.

- Improved Working Conditions: Lowers oil mist concentration, enhancing worker health and comfort.

- Extended Equipment Life: Keeps machine parts clean, reducing corrosion and wear from oil mist.

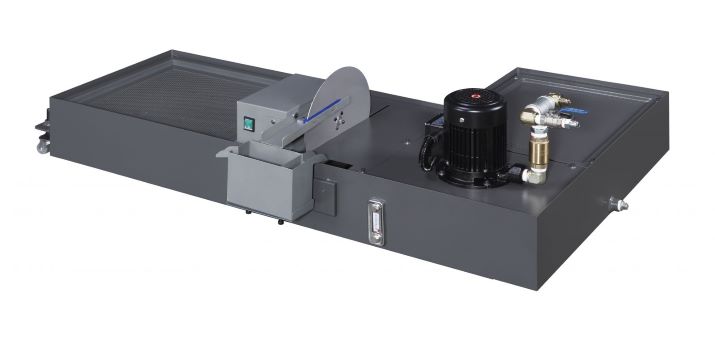

Oil Skimmer

- Recycling opportunities: to re-use the skimmed oil elsewhere or sell it for recycling.

- Extend coolant life: to have oil free coolant can also extend its usefulness and effectiveness, reducing the expense on maintenance and coolant replacement.

- Esthetic benefits: to cut down on the amount of smoke generated from the cutting tool coming into contact with coolant thereby creating a cleaner workplace.