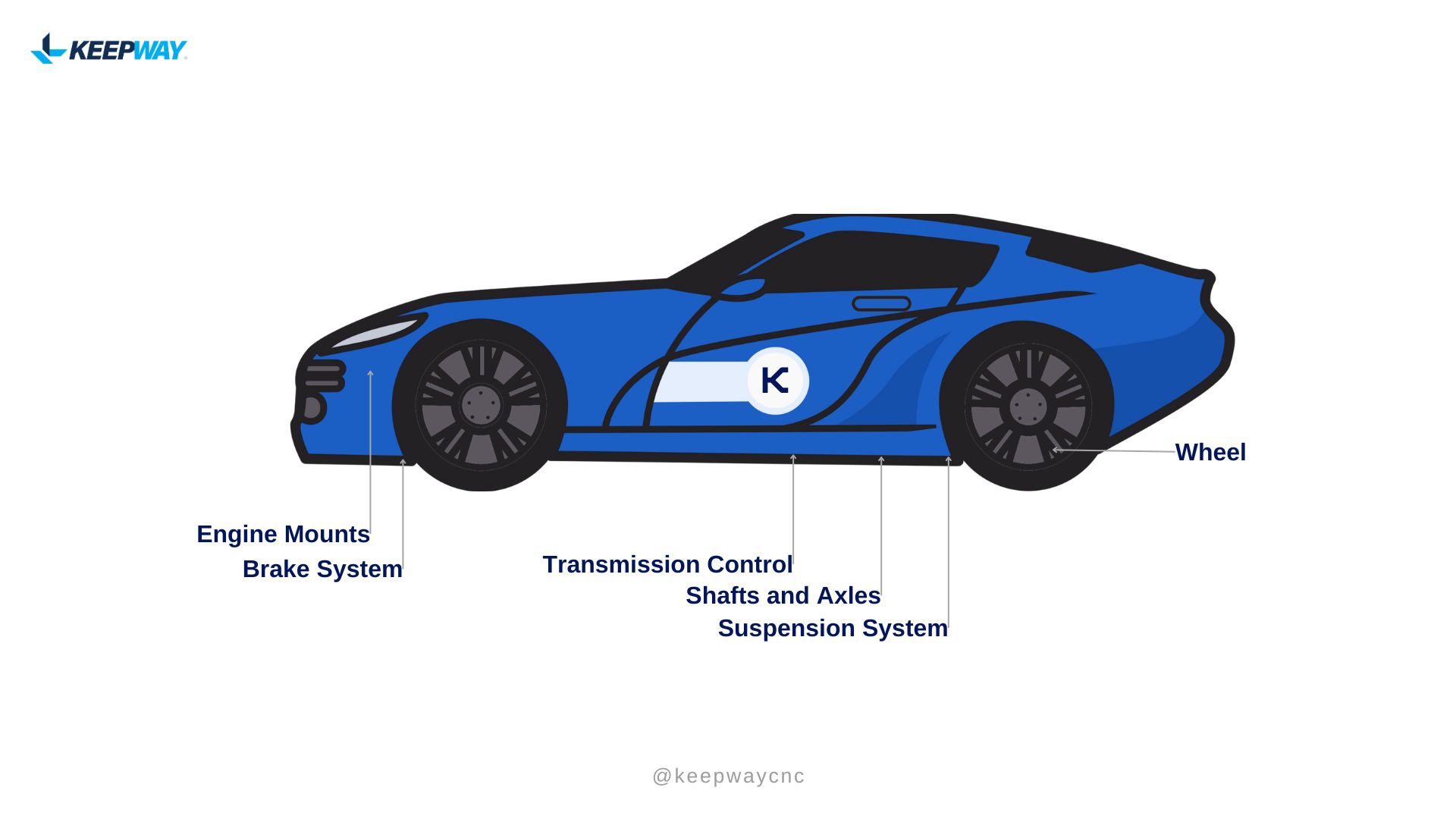

The Automoive Industry

Turning Centers (CNC Lathes)

Engine Components: CNC lathes are used to manufacture crucial engine parts such as crankshafts, camshafts, and cylinder heads. These components require high precision to ensure the engine operates smoothly and efficiently.

Drive Shafts and Axles: These parts must be accurately machined to fit perfectly and handle the stresses of driving.

Brake System Components: CNC lathes produce brake discs and drums, which need to meet exact specifications for safety and performance.

Transmission Parts: Gears and other transmission components are machined with tight tolerances to ensure proper functioning of the vehicle's transmission system.

Machining Centers

Complex Engine Parts: Machining centers are used to produce intricate parts like engine blocks and heads, which have complex geometries and require multiple machining operations.

Chassis and Suspension Components: These parts often have complex shapes and need high-strength materials, which CNC machining centers can handle effectively.

Interior and Exterior Components: Machining centers are used to manufacture various components such as dashboard panels, trim parts, and other interior fittings that require precision and smooth finishes.

Prototyping and R&D: CNC machining centers are essential for creating prototypes of new components quickly and accurately, aiding in the research and development process for new vehicle models.

The Advantages

Precision and Accuracy: Both CNC lathes and machining centers provide the high precision required for automotive parts, ensuring that components fit and function perfectly.

Efficiency and Speed: CNC machines can operate continuously with minimal human intervention, significantly speeding up production processes.

Flexibility: CNC machines can be programmed to produce a wide range of parts, allowing manufacturers to quickly switch between different components as needed.

Consistency: CNC machines produce parts with consistent quality, reducing the variability and defects that can occur with manual machining.

The use of CNC lathes and machining centers in the automobile industry enhances the production of high-quality, precise, and reliable components. These machines are crucial in manufacturing various engine parts, drive systems, chassis components, and interior and exterior elements, playing a significant role in the efficiency and advancement of automotive manufacturing processes.

Turning Center

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 500mm

Turning Center

Chuck size: 12"

Max turning diameter: 460mm

Max turning length: 1100mm

Machining Center

X-axis Travel: 1600mm

Y-axis Travel: 800mm

Z-axis Travel: 700mm

Turning Center

Chuck size: 10"

Max turning diameter: 360mm

Max turning length: 700mm

Turning Center

Chuck size: 8"

Max turning diameter: 210mm

Max turning length: 450mm

Turning Center

Chuck size: 8"

Sub-spindle chuck size: 6"

Max turning diameter: 220mm

Max turning length: 450mm

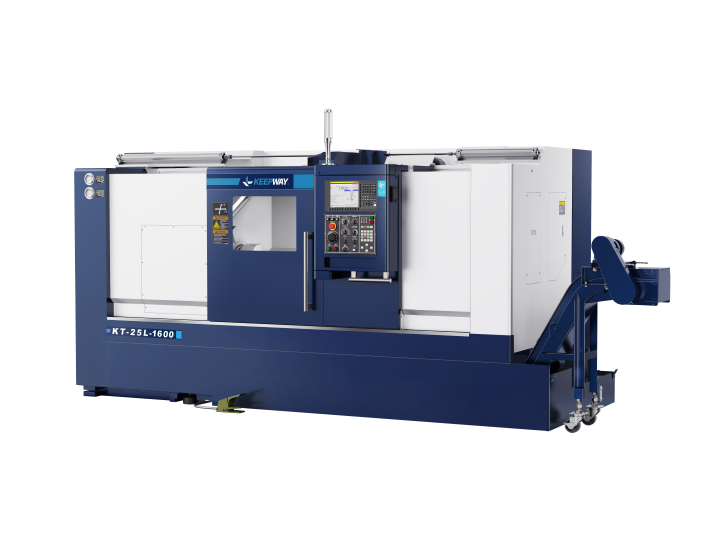

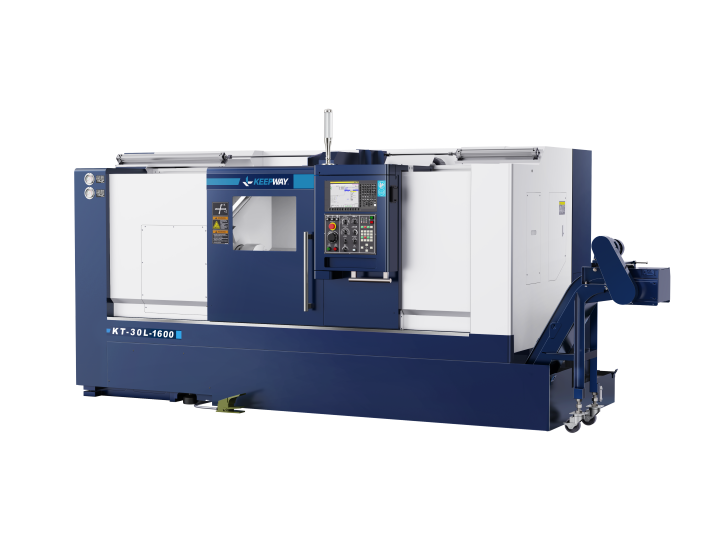

Turning Center

Chuck size: 10"

Max turning diameter: 360mm

Max turning length: 1600mm

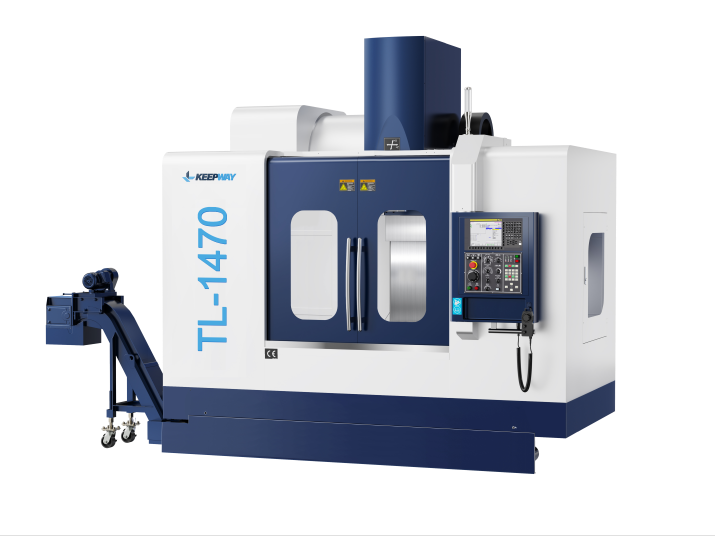

Machining Center

X-axis Travel: 1400mm

Y-axis Travel: 700mm

Z-axis Travel: 600mm

Turning Center

Chuck size: 10"

Max turning diameter: 210mm

Max turning length: 450mm

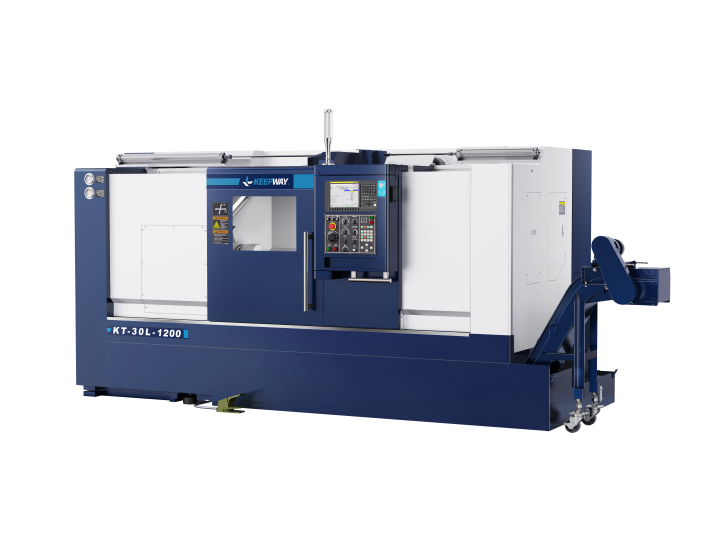

Turning Center

Chuck size: 12"

Max turning diameter: 580mm

Max turning length: 1200mm

Turning Center

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 700mm

Turning Center

Chuck size: 10"

Max turning diameter: 360mm

Max turning length: 500mm

Machining Center

X-axis Travel: 1200mm

Y-axis Travel: 600mm

Z-axis Travel: 600mm

Turning Center

Chuck size: 10"

Max turning diameter: 360mm

Max turning length: 1200mm

Turning Center

Chuck size: 10"

Max turning diameter: 210mm

Max turning length: 700mm

Machining Center

X-axis Travel: 1000mm

Y-axis Travel: 600mm

Z-axis Travel: 600mm

Automation Solution

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 500mm

Turning Center

Chuck size: 10"

Max turning diameter: 360mm

Max turning length: 750mm

Turning Center

Chuck size: 12"

Max turning diameter: 460mm

Max turning length: 650mm

Automation Solution

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 500mm

Turning Center

Chuck size: 12"

Max turning diameter: 580mm

Max turning length: 750mm

Turning Center

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 450mm

Machining Center

X-axis Travel: 750mm

Y-axis Travel: 500mm

Z-axis Travel: 500mm

Turning Center

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 750mm

Turning Center

Chuck size: 15"

Max turning diameter: 580mm

Max turning length: 1180mm

Turning Center

Chuck size: 8"

Max turning diameter: 360mm

Max turning length: 500mm

Turning Center

Chuck size: 10"

Max turning diameter: 360mm

Max turning length: 450mm

Turning Center

Chuck size: 10"

Max turning diameter: 360mm

Max turning length: 1100mm

Turning Center

Chuck size: 12"

Max turning diameter: 580mm

Max turning length: 1600mm