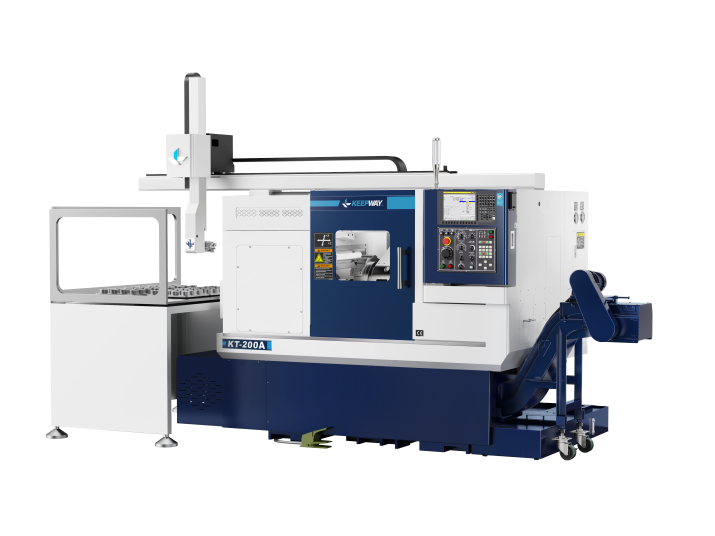

Turning Center

KT-200M

KT Series [Multi-Axis]

The KT series lathe, combined with the B-axis and C-axis, creates a multi-axis turn-mill composite machine.

This integration allows for combined turning and milling, addressing complex machining needs unmet by traditional lathes.

Direct-drive motors on the X/Z/B axes minimize backlash and vibration, ensuring high repeatability and positioning accuracy.

Hand Scraping Techniques

- The utilization of manual scraping techniques significantly enhances machining precision, operational stability, and the overall durability of the machine tool.

- These techniques guarantee impeccable alignment among diverse components, thereby equipping the machine tool to effectively address a multitude of intricate machining tasks.

Ball Screw

- All our products are equipped with high class ball screws, ensuring high positioning accuracy.

- We employ a ball screw pretension design across all axes to effectively minimize the need for backlash compensation in the machine body.

- This results in exceptional repeatability and positioning accuracy.

Spindle

- The headstocks feature one-piece castings. We install high-precision bearings from NSK/TNT, renowned for their capacity to withstand heavy bearing loads, delivering exceptional precision and durability performance.

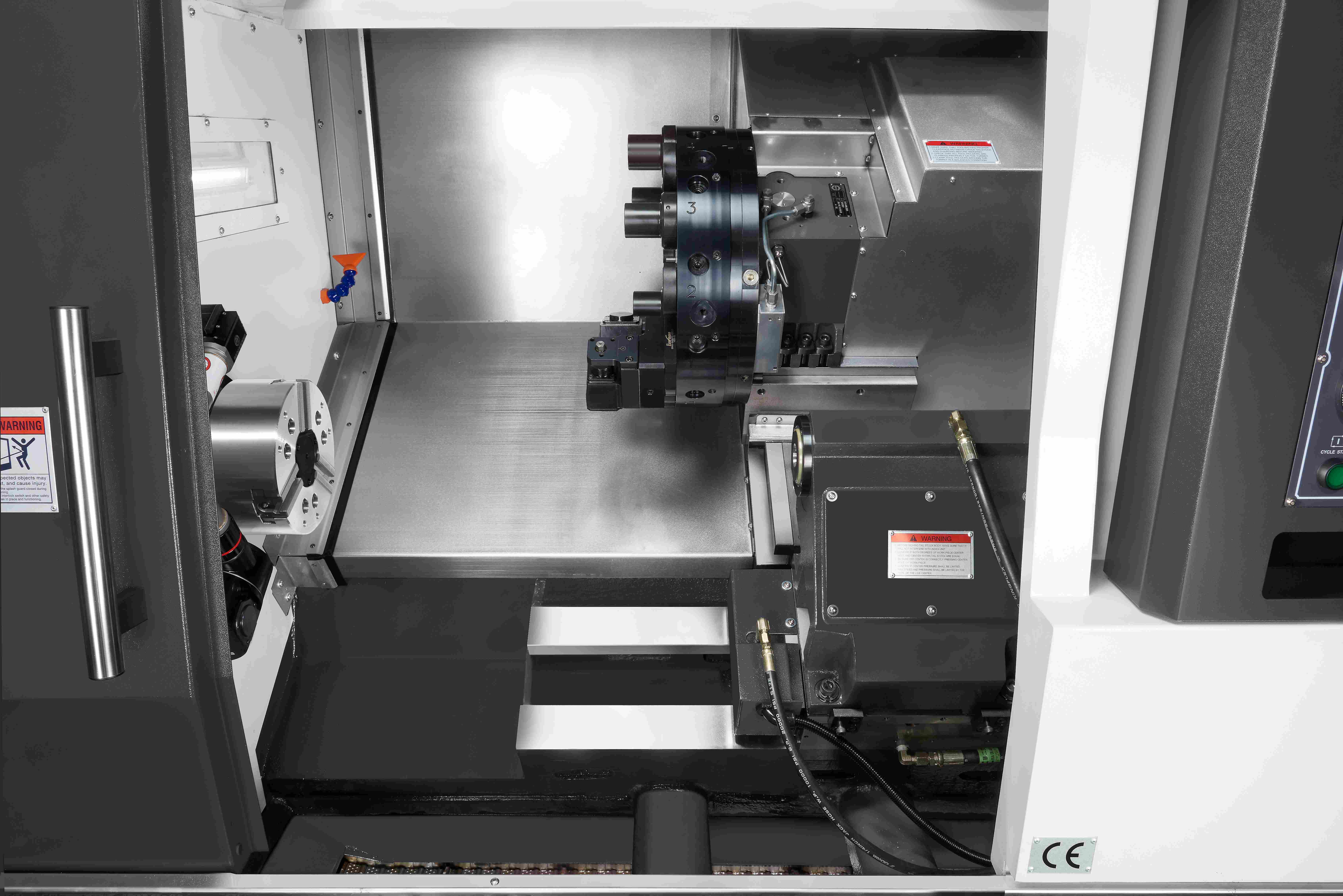

Power Turret

- Power turrets can accommodate a variety of tools, including turning tools, boring bars, drills, and live tooling for milling operations.

- This versatility allows for a wide range of machining processes without the need to change the workpiece's setup.

| Item | KT-200M |

|---|---|

| Controller | Fanuc 0i-TF Plus |

| Bed swing diameter | 530 mm |

| Saddle swing diameter | 380 mm |

| Maximum turning diameter | 360 mm |

| Maximum turning length | 500 mm |

| Bar capacity | 52 mm |

| Power chuck diameter | 8” |

| Spindle motor power | 11/15 kw |

| Spindle speed | 4500 rpm |

| Spindle nose taper | A2-6 |

| Spindle bearing diameter | 100 mm |

| Spindle taper | 1/20 |

| X-axis travel | 180+20 mm |

| Z-axis travel | 500 mm |

| X-axis rapid feed rate | 24 m/min |

| Z-axis rapid feed rate | 24 m/min |

| Guide way type | Box |

| Turret driven type | Servo |

| Tool capacity | 10T |

| OD tool shank size | 25 mm |

| ID tool shank size | 32 mm |

| Tailstock travel positioning | Hydraulic |

| Tailstock quill travel | 110 mm |

| Tailstock base travel | 425 mm |

| Quill taper size | MT#4 |

| Quill taper diameter | 70 mm |

| Floor space (LxWxH) | 3318x1675x1727 mm |

| Machine weight | 4000 kg |

DISCLAIMER : KAIFENG MACHINERY CO., LTD. RESERVES THE RIGHT TO AMEND ANY SPECIFICATIONS WITHOUT PRIOR NOTICE.

| Item | KT-200M |

|---|---|

| Controller | Fanuc 0i-TF Plus |

| Bed swing diameter | 20.9” |

| Saddle swing diameter | 15.0” |

| Maximum turning diameter | 14.2” |

| Maximum turning length | 19.7” |

| Bar capacity | 2.0” |

| Power chuck diameter | 8” |

| Spindle motor power | 11/15 kw |

| Spindle speed | 4500 rpm |

| Spindle nose taper | A2-6 |

| Spindle bearing diameter | 3.9” |

| Spindle taper | 1/20 |

| X-axis travel | 7.1+0.8” |

| Z-axis travel | 19.7” |

| X-axis rapid feed rate | 24 m/min |

| Z-axis rapid feed rate | 24 m/min |

| Guide way type | Box |

| Turret driven type | Servo |

| Tool capacity | 10T |

| OD tool shank size | 1.0” |

| ID tool shank size | 1.3” |

| Tailstock travel positioning | Hydraulic |

| Tailstock quill travel | 4.3” |

| Tailstock base travel | 16.7” |

| Quill taper size | MT#4 |

| Quill taper diameter | 2.8” |

| Floor space (LxWxH) | 3318x1675x1727 mm |

| Machine weight | 4000 kg |

DISCLAIMER : KAIFENG MACHINERY CO., LTD. RESERVES THE RIGHT TO AMEND ANY SPECIFICATIONS WITHOUT PRIOR NOTICE.

Gantry Loading and Unloading System

- A Gantry Loading/Unloading System, when used with a CNC machine, is an automated material handling system designed to load and unload workpieces into and out of the lathe's work area.

- Increased Productivity: Automation reduces downtime between machining operations, leading to higher throughput and productivity.

- Reduced Labor Costs: Operators are freed up to perform more skilled tasks or oversee multiple machines, reducing the need for dedicated machine tenders.

- 24/7 Operation: Automated systems can run continuously, allowing for unmanned machining during nights or weekends.

Bar Feeder

- The optional automatic bar feeder enhances productivity by reducing material feeding time. It imposes no limitations on spindle speed or material shape.

- Various feeding torques can be applied to accommodate different material diameters, weights, and lengths, preventing material deformation.

Parts Catcher

- The parts catcher automatically receives finished parts, offering convenient access without the need to open the machine door. This highly efficient system is operator friendly.

Tool Presetter

- The optional Renishaw or Marposs tool probe accessory significantly boosts production output and minimizes machine idle time.

- It precisely measures cutting tool length and diameter, providing solutions for tool setting, broken tool detection, component setup, in-cycle gauging, and initial component inspection, with automatic offset updates.

Oil Mist Collector

- Environmental Protection: Effectively collects and recycles oil mist, reducing air pollution and protecting the work environment.

- Cost Reduction: Recovered oil mist can be reused, lowering the consumption costs of lubricating oil.

- Enhanced Safety: Reduces the accumulation of oil mist in the workplace, decreasing the risk of fire and slips.

- Improved Working Conditions: Lowers oil mist concentration, enhancing worker health and comfort.

- Extended Equipment Life: Keeps machine parts clean, reducing corrosion and wear from oil mist.

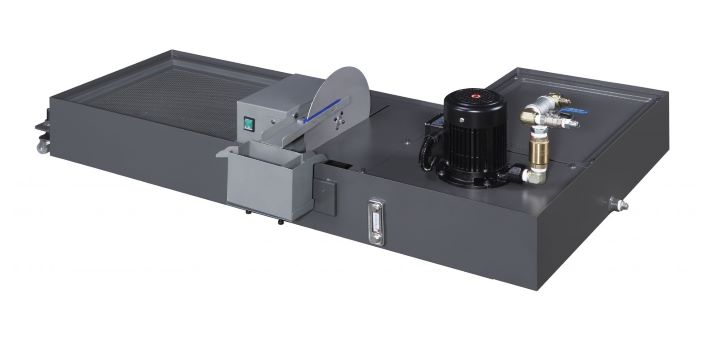

Oil Skimmer

- Recycling opportunities: to re-use the skimmed oil elsewhere or sell it for recycling.

- Extend coolant life: to have oil free coolant can also extend its usefulness and effectiveness, reducing the expense on maintenance and coolant replacement.

- Esthetic benefits: to cut down on the amount of smoke generated from the cutting tool coming into contact with coolant thereby creating a cleaner workplace.