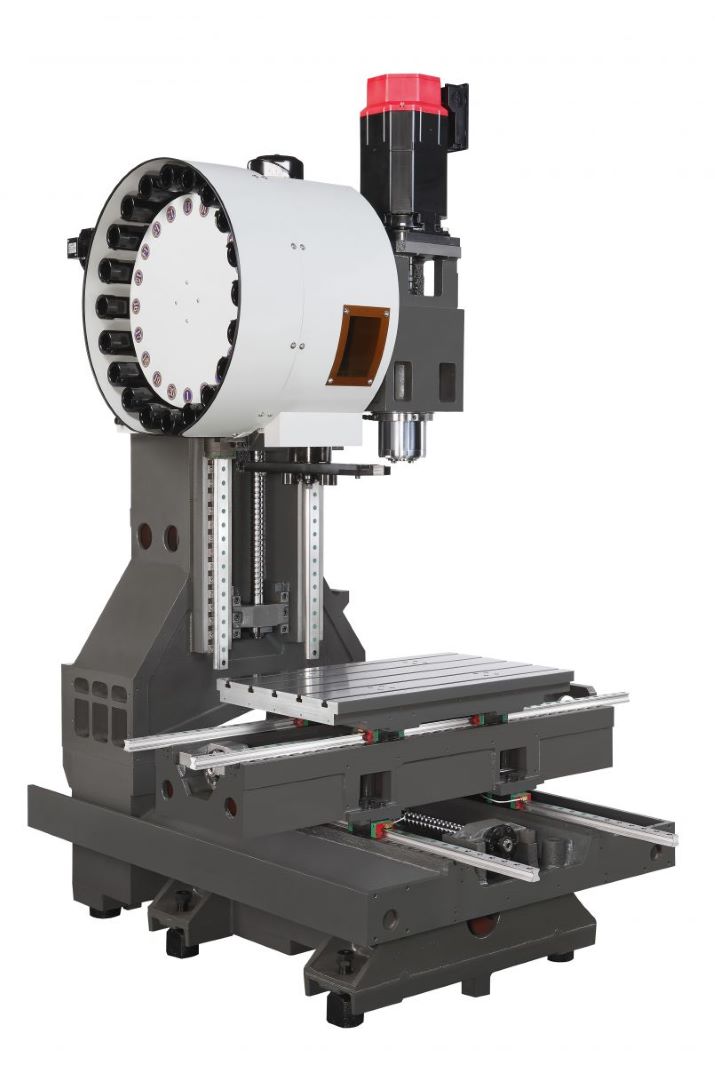

Machining Center

TLU-400

TLU Series

The TLU series 5-axis multi-tasking milling centers are advanced, versatile solutions designed to optimize and enhance high precision complexity production processes.

It offers efficient machining from multiple angles without needing multiple setups, reducing cycle times and increasing productivity.

Structure Design

- We use MIT castings for our machining center's body structure, ensuring top quality for our users.

- This choice maintains precise accuracy during metal cutting and extends the lifespan of cutting tools.

- The Y-shaped interior design provides strong support, enhancing overall precision and performance.

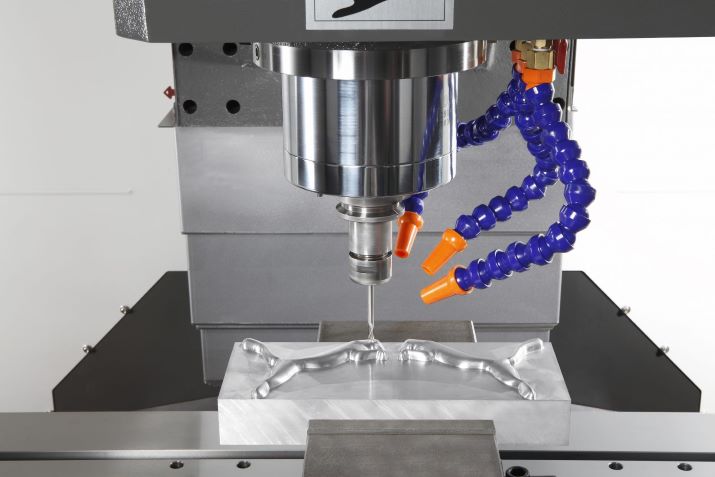

Spindle

- High Speeds: Direct-driven spindles can achieve very high rotational speeds, allowing for faster cutting and machining operations. This is particularly advantageous when precision and speed are critical.

- Improved Accuracy: Direct-driven spindles typically have better speed control and accuracy compared to belt-driven or gear-driven spindles. This precision is essential for achieving tight tolerances and high-quality surface finishes.

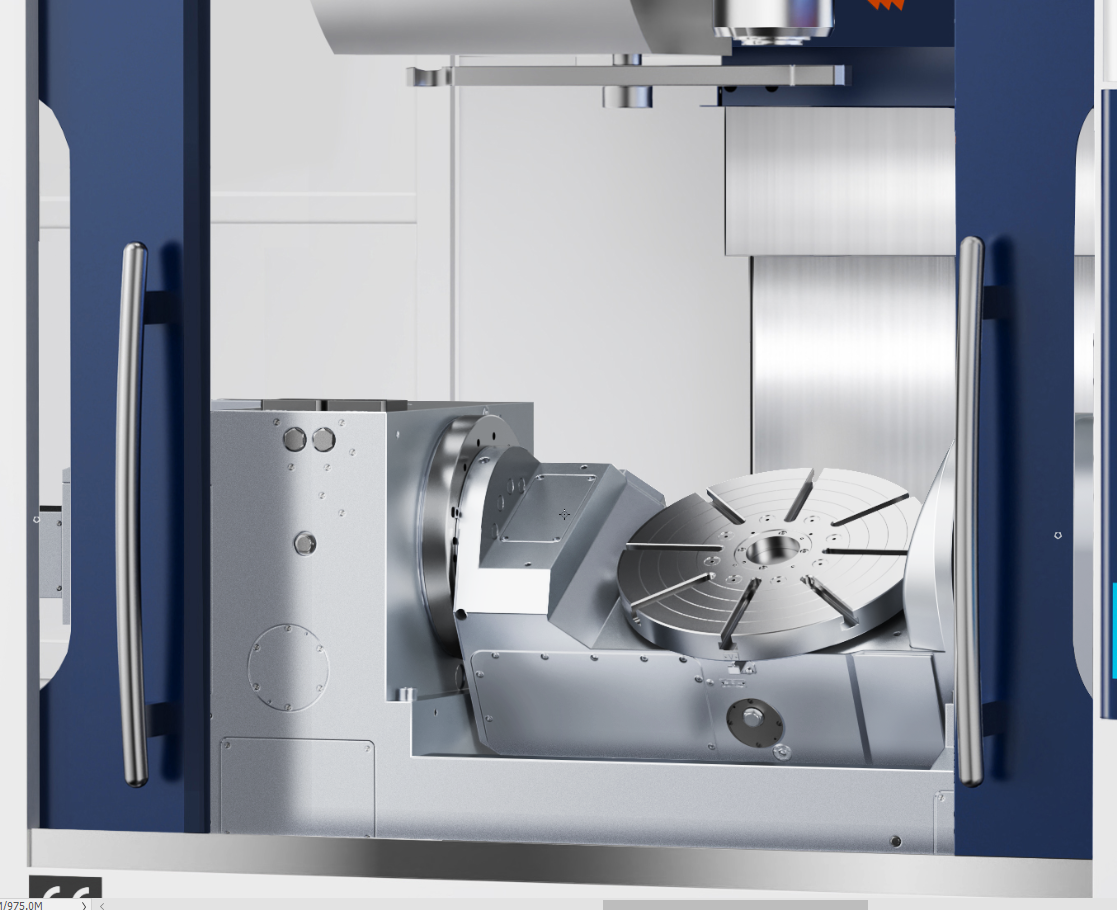

Multi-Tasking 5-Axis

- 5-Axis machines utilize the standard X, Y, and Z axes in conjunction with the A and B axes, allowing the tools to access all five sides of a part without the need for additional turning or setups.

- By using a multi-task 5-axis machine, you can reduce the number of setups, shorten cycle times, increase spindle uptime and enhance high precision.

Rotary Table

- The TLU Series is equipped with an A/B-axis Rotary Table, designed to boost versatility and precision. The A-axis offers a wide tilting range, allowing for enhanced flexibility when processing complex geometries.

- The rotary table is precisely aligned with the 5th axis centerline, guaranteeing superior accuracy during fixture applications. This alignment significantly improves the machining process's efficiency and adaptability.

| Item | TLU-400 |

|---|---|

| Controller | Fanuc 0i-MF Plus |

| Spindle motor | 11/15 kw |

| X/Y/Z axis motor | 3.0/3.0/3.0 kw |

| Coolant pump motor | 600 w |

| Magazine motor | 400 w |

| Chip conveyor motor | 600 w |

| Spindle driven type | Direct |

| Spindle Speed | 10000 rpm |

| Spindle taper | BT-40 |

| Spindle diameter | Φ150 mm |

| Spindle bearing grade | P4 |

| X-axis travel | 500 mm |

| Y-axis travel | 600 mm |

| Z-axis travel | 550 mm |

| Spindle nose to table | 650 mm |

| Ballscrew grade | C3 |

| X/Y/Z ballscrew | X: Φ40xP12, Y/Z: Φ45xP12 |

| X/Y/Z linear guideway | 35/45/45 |

| X/Y/Z cutting feed rate | 10/10/10 m/min |

| X/Y/Z rapid feed rate | 36/36/24 m/min |

| Rotary table size | Φ410 mm |

| Maximum table load | 150-200 kg |

| Tilting angle range | -120~+30° |

| Magazine type | Arm |

| Tool capacity | 24 |

| Tool selection | Two-way Selection |

| Maximum tool length / diameter | 250xΦ150 |

| Maximum tool weight | 7 kg |

| Tool shank | 45° |

| Chip conveyor | Belt type |

| Air pressure | ≧6.5 |

| Power voltage | 220/380 v |

| Power capacity | 20 kva |

| Floor space (LxWxH) | 3708x2380x2884 mm |

| Machine Weight | 6800 kg |

DISCLAIMER : KAIFENG MACHINERY CO., LTD. RESERVES THE RIGHT TO AMEND ANY SPECIFICATIONS WITHOUT PRIOR NOTICE.

| Item | TLU-400 |

|---|---|

| Controller | Fanuc 0i-MF Plus |

| Spindle motor | 11/15 kw |

| X/Y/Z axis motor | 3.0/3.0/3.0 kw |

| Coolant pump motor | 600 w |

| Magazine motor | 400 w |

| Chip conveyor motor | 600 w |

| Spindle driven type | Direct |

| Spindle Speed | 10000 rpm |

| Spindle taper | BT-40 |

| Spindle diameter | Φ150 mm |

| Spindle bearing grade | P4 |

| X-axis travel | 19.7” |

| Y-axis travel | 23.6” |

| Z-axis travel | 21.7” |

| Spindle nose to table | 25.6” |

| Ballscrew grade | C3 |

| X/Y/Z ballscrew | X: Φ40xP12, Y/Z: Φ45xP12 |

| X/Y/Z linear guideway | 4/6/6 |

| X/Y/Z cutting feed rate | 10/10/10 m/min |

| X/Y/Z rapid feed rate | 36/36/24 m/min |

| Rotary table size | Φ410 mm |

| Maximum table load | 150-200 kg |

| Tilting angle range | -120~+30° |

| Magazine type | Arm |

| Tool capacity | 24 |

| Tool selection | Two-way Selection |

| Maximum tool length / diameter | 250xΦ150 |

| Maximum tool weight | 7 kg |

| Tool shank | 90° |

| Chip conveyor | Belt type |

| Air pressure | ≧6.5 |

| Power voltage | 220/380 v |

| Power capacity | 20 kva |

| Floor space (LxWxH) | 3708x2380x2884 mm |

| Machine Weight | 6800 kg |

DISCLAIMER : KAIFENG MACHINERY CO., LTD. RESERVES THE RIGHT TO AMEND ANY SPECIFICATIONS WITHOUT PRIOR NOTICE.