October 15, 2024

BlogHow do CNC lathes specifically contribute to the production of EV parts?

CNC lathes play a crucial role in the production of electric vehicle (EV) parts by providing high precision, efficiency, and customization capabilities. Here are some keyways CNC lathes contribute to EV part manufacturing:

- Motor and Drivetrain Components:

- CNC lathes are used to manufacture precision motor shafts and housings, which are critical for the efficiency and performance of electric motors[1].

- They also produce rotor shafts, stator assemblies, and cooling fins, all of which are essential for maximizing the power production and efficiency of electric motors[4].

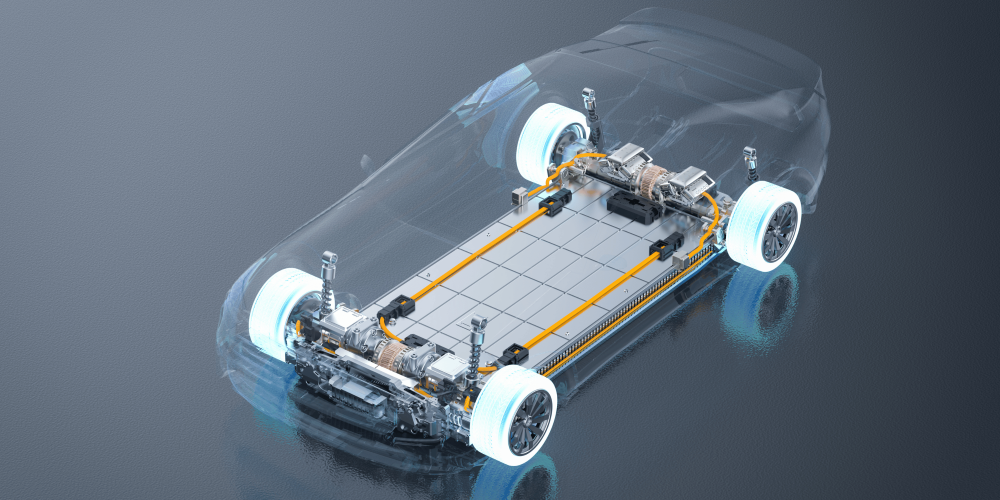

- Battery Enclosures and Frames:

- CNC lathes are used to create precise battery enclosures and frames that meet exact specifications for safety and durability. These components are crucial for protecting the battery pack and ensuring the vehicle's structural integrity[1][4].

- Cooling Systems:

- CNC lathes are involved in the production of complex cooling system components, such as intricate cooling fins and channels, which are necessary for managing heat generated by batteries and motors[1][4].

- Structural Components:

- CNC lathes are used to fabricate structural components like chassis parts, suspension components, and frame reinforcements. These precision-engineered components are critical for maintaining the vehicle's stability, rigidity, and crashworthiness while reducing weight and increasing energy efficiency[4].

- Interior and Exterior Trim:

- CNC lathes enable the manufacture of interior and exterior trim components, such as dashboard panels, door handles, grille inserts, and trim accents. These aesthetically beautiful components improve the vehicle's overall appearance and functionality[4].

- Regenerative Braking Systems:

- CNC lathes are used to manufacture components for regenerative braking systems, including brake calipers, rotors, pads, and brake discs. These precision-machined parts optimize braking performance, energy recovery, and overall driving efficiency[4].

Benefits of CNC Lathes in EV Production:

- Precision and Quality: CNC lathes offer unparalleled accuracy, ensuring that parts meet demanding specifications, which is crucial for high-performance and safety standards in EVs[1][2].

- Consistency: The same process is repeated every time, leading to consistent and repeatable results, ensuring improved vehicle performance and reliability[2].

- Customization and Flexibility: CNC lathes allow for easy customization and quick adjustments to the machining process, enabling manufacturers to respond to design or production changes without sacrificing quality[2][4].

- Speed and Efficiency: CNC lathes can operate 24/7 and automate complex processes, reducing production times and increasing efficiency[1][2].

- Reduced Waste: CNC lathes precisely cut only the required material, reducing waste and material costs[2].

- Improved Safety: CNC lathes eliminate the need for manual cutting, reducing the risk of workplace accidents and allowing for continuous production[2].

In summary, CNC lathes are essential for producing precision components that are critical to the performance, safety, and efficiency of electric vehicles. Their ability to provide high precision, efficiency, and customization makes them a vital tool in the production of EV parts.

Citations:

[1] https://www.steckermachine.com/blog/electric-vehicle-manufacturing-and-cnc-machining

[2] https://www.linkedin.com/pulse/cnc-machining-electric-vehicles-manufacturing-primer

[5] https://cimquest-inc.com/electric-vehicles-and-cnc-machining-what-you-need-to-know/